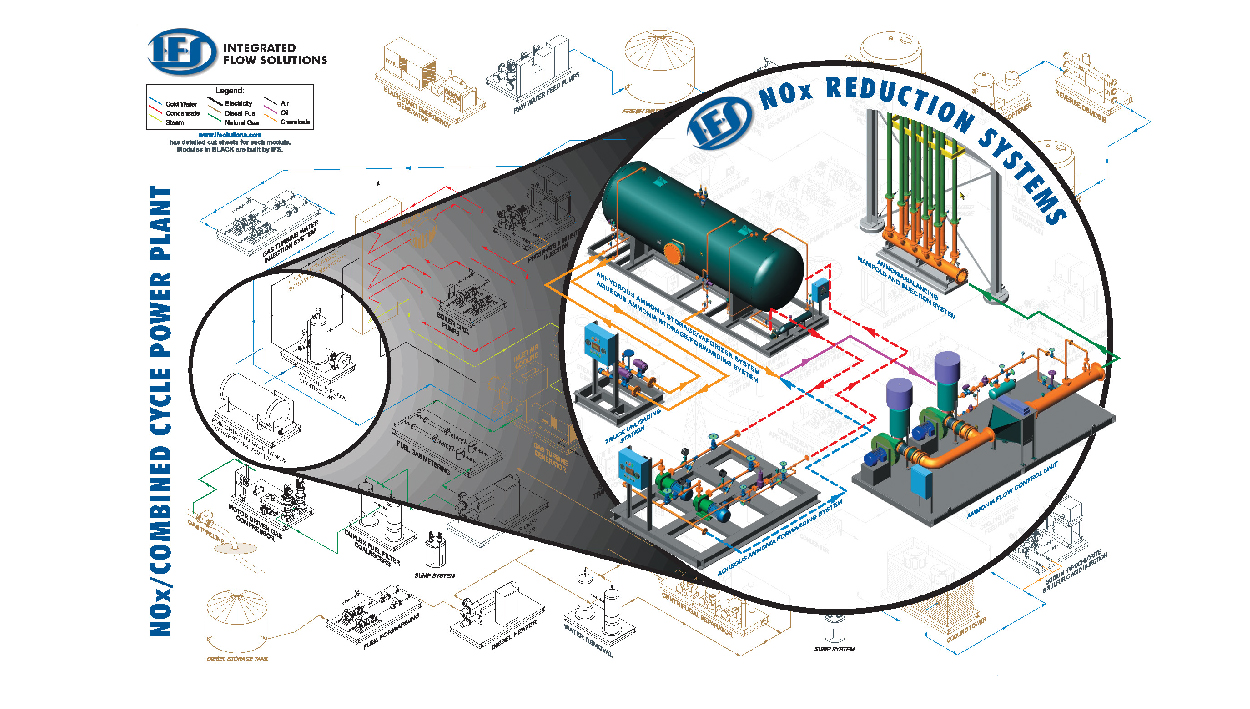

Natural Gas Pressure Reduction Station Package

Skid-Mounted Modular System, Engineered-to-Order

Skid-Mounted Modular System, Engineered-to-Order

Integrated Flow Solutions Gas Pressure Reduction Stations are pre-designed, packaged and fully tested for a wide range of pipeline applications. The complete system includes a process simulation using Aspen Plus® and Aspen Dynamics®, local control panel, instruments, tubing, valves, fast acting and motor actuators, and filtration integrated on skid.

This package can be modified as a Compressed Natural Gas (CNG) Decanter System.

Benefits:

- Single Source Accountability

- Pre-Packaged Modular Design Costs Less than component based site built which reduces overall project cost

- Minimizes field erection time – shorter overall project delivery schedule

|

- Complete system function testing prior to shipment

- 24/7 Customer service (800-527-8724)

|

Industry Standards:

- Local Control Panel designed to NEC, CSA, or IEC

- Piping/tubing designed to ANSI B31.3/ANSI B31.8

|

- Structural Steel Assembly Designed to AWS D1.1

|

Standard Features:

- Reduced Port

- Sized for 80 PSI Instrument Air Supply

- Plated Trim Materials

- Carbon Steel Materials

|

- Fire Safe

- Open Beam Skid

- Dual Scale Liquid Filled Pressure Gauges

|

Optional Features:

- Full Port

- Sized for 60 PSI Instrument Air Supply

- Actuators designed for Instrument Gas Supply

- Hot Backup Redundant Control

- 316 SS Trim Materials

- 350-LF2 Materials

- High Temperature Seats

- Low Temperature Seats

- Discharge Pressure Instrumentation

|

- Oversized Skid

- Skid Drain Pan

- Custom Skid Decking

- Custom Paint

- 4-20 mA Feedback

- Manual Override System

- Jack Screw Type

- De-Clutchable Type

|

Additional Services:

- Installation / Training / Start – Up Supervision

- Extended warranty

|

- Worldwide Service Network

- Customized Systems

|

Skid-Mounted Modular System, Engineered-to-Order

Skid-Mounted Modular System, Engineered-to-Order